$170,817.08

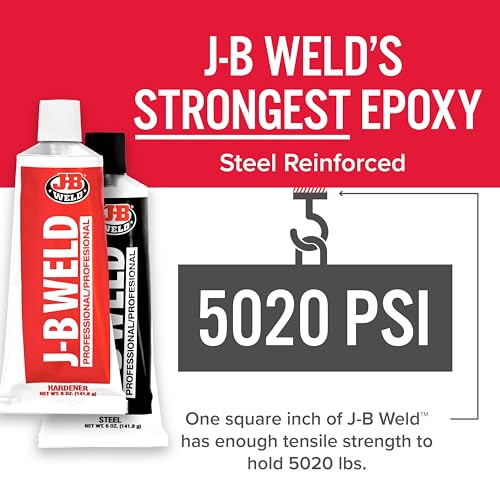

Unleash the power of J-B Weld 8281 Professional Size Steel Reinforced Epoxy! 💪✨

- Versatile & Reliable: Perfect for repairs on metal, hard plastics, and more.

- Strong & Durable: Trusted by professionals for unbeatable bond strength.

- Easy to Use: Mix and apply with ease; just ensure surfaces are clean!

- Long-lasting Results: After a slow cure, expect repairs that withstand the test of time.

Don’t settle for less—upgrade your toolkit today and tackle any repair job with confidence! 🛠️ Grab yours now!

Description

Discover the Ultimate Solution for Repairs: J-B Weld 8281 Professional Size Steel Reinforced Epoxy

Are you tired of unreliable adhesives that just don’t hold up? Look no further! The J-B Weld 8281 Professional Size Steel Reinforced Epoxy is here to transform your repair game. This powerful epoxy is designed for those who demand strength, versatility, and reliability in their repairs.

Why J-B Weld?

-

Steel Reinforced Power: This isn’t just any epoxy; it’s steel reinforced! The unique formula creates a bond that rivals traditional welding, making it the perfect choice for metal repairs, automotive projects, and household fixes.

-

Versatile Applications: From automotive repairs to household projects, J-B Weld is a true lifesaver! Users rave about its effectiveness in a variety of situations, from fixing broken brass idols to mending metal engines. The possibilities are endless!

Customer Love: Real Stories, Real Results

Don’t just take our word for it! Here’s what some satisfied customers are saying:

-

A Diesel Mechanic’s Best Friend: One satisfied customer, with 18 years of experience as a diesel mechanic, praises the slow-curing epoxy for its ability to save both time and money on repairs. When used correctly, it fills gaps and creates an incredibly durable bond that stands the test of time.

-

Exceptional Weight Support: Another user successfully used J-B Weld to repair an 80lb brass idol. They found it exceeded expectations, providing a bond strong enough to hold substantial weight. Just remember to allow 24-48 hours for it to cure fully, and your repair will be as good as new!

-

Expertly Durable: Reviewers agree that J-B Weld is the best epoxy repair on the market. Its ease of use, combined with its exceptional durability, makes it the go-to choice for both amateur DIYers and professional tradespeople alike.

Features You’ll Love

-

Easy Application: Mixing the two components is a breeze! Use a tongue depressor or similar tool for a smooth application. No more complicated processes—just mix and apply!

-

Long Working Time: One of the standout features of J-B Weld is its long open time, giving you plenty of opportunity to work with the product until you achieve the perfect application.

-

Paintable and Sandable: Once cured, this epoxy can be sanded down or painted over, making it an ideal choice for repairs that need to blend seamlessly with the surrounding material.

When to Use J-B Weld

If you’re facing any of the following challenges, it’s time to reach for J-B Weld:

-

Metal Repairs: Whether you’re dealing with a hole in your vehicle or a rusted part, J-B Weld is your go-to solution.

-

Hard Plastic Fixes: This epoxy isn’t just for metal! It works wonders on hard plastics, too, making it an all-around adhesive solution.

-

Filling Gaps: The minimal shrinkage and excellent gap-filling properties make J-B Weld perfect for those tricky repair jobs.

Tips for Success

To get the best results from J-B Weld, consider these expert tips:

-

Clean Thoroughly: Always ensure the surfaces are clean and degreased before applying the epoxy. A clean surface is vital for achieving a strong bond.

-

Temperature Matters: Keep in mind that curing time can vary with temperature. The colder it is, the longer it may take to cure. Patience is key for the best results!

-

Allow Proper Cure Time: For best results, give the epoxy time to cure fully before putting any load or pressure on the repair. This ensures maximum strength and durability.

The Perfect Choice for DIY Enthusiasts and Professionals

With a product dimension of 1.77 x 6.5 x 8.46 inches and a weight of 3.2 ounces, the J-B Weld 8281 Professional Size Steel Reinforced Epoxy is compact yet powerful. Whether you’re a DIY enthusiast tackling small projects or a professional looking for a reliable adhesive for larger jobs, this epoxy fits the bill!

Join the J-B Weld Community!

When you choose J-B Weld, you’re not just buying a product; you’re joining a community of satisfied users who trust in its strength and versatility. Don’t miss out on the chance to experience the difference for yourself!

Ready to Repair?

Don’t let broken items linger any longer! Grab your J-B Weld 8281 Professional Size Steel Reinforced Epoxy today and discover the power of a truly reliable adhesive. Click the “Add to Cart” button and start your journey to hassle-free repairs now!

Your projects deserve the best—choose J-B Weld and never look back!

This description is crafted to engage and inspire potential customers, highlighting the incredible benefits of J-B Weld while providing a clear call to action. Experience the difference today!

Additional information

| Is Discontinued By Manufacturer | No |

|---|---|

| Product Dimensions | 1.77 x 6.5 x 8.46 inches, 3.2 ounces |

| Item model number | 8281 |

| Department | Unisex-Adult |

| Date First Available | August 31, 2015 |

| Manufacturer | J-B Weld Store |

| Country of Origin | China |

13 reviews for J-B Weld 8281: Ultimate Steel Reinforced Epoxy 10 oz

Related products

-

Sale!

Sale!

J-B Weld ClearWeld Pro: Fast, Strong, Transparent Epoxy

4.89 out of 5$41.00Original price was: $41.00.$39.00Current price is: $39.00. Add to cart -

J-B Weld Plastic Bonder: Quick-Set Adhesive & Gap Filler

4.92 out of 5$28.00 Add to cart -

J-B Weld SuperWeld Glue – Instant Bonding Power, 20g

4.46 out of 5$26.00 Add to cart -

6-Pack Heavy-Duty Weld-On Grab Hooks for Versatile Use

4.88 out of 5$42.00 Add to cart

Someone –

Just as described.

Jennifer Mills –

I used this epoxy to secure some loose components in my vehicle. While it takes a while to cure, it’s definitely effective! It can be a bit messy, so I recommend prepping a surface for mixing. Application was a breeze with just a tongue depressor, and it has kept the parts firmly in place.

Tim R –

J-B Weld Steel Reinforced Epoxy is a game-changer! I’ve utilized this product for countless repairs and projects, and it consistently delivers outstanding results. It mixes easily and is simple to work with. The bond is incredibly strong; I’ve never encountered a failure with this product.

Ashley ODONNELL –

I’m genuinely impressed with this epoxy adhesive! The professional size offers great value, and the bond strength is outstanding. It truly excels in every aspect. I highly recommend it!

Ángel –

The best cement I’ve ever used; it’s exactly as advertised, similar to a weld, durable, and easy to apply.

Stoney –

WHEN TO USE EPOXY CEMENT

Epoxy is typically the go-to adhesive when you need a strong, rigid, and workable surface, especially for metals or hard plastics. Most epoxy formulations dry with minimal running or shrinkage, making them effective for filling gaps. However, a significant drawback is that epoxies are composed of two parts (resin and hardener) that must be mixed in small batches, requiring your own applicator (like a toothpick or popsicle stick). Some come in dual-syringe packaging, but you still need to mix the components manually for optimal strength.

WHEN TO USE JB-WELD

JB-Weld is a robust epoxy cement primarily recommended for bonding metal parts or filling holes in metals. For other applications, standard epoxy or alternative adhesives might be more suitable. Some users argue that the term “weld” is misleading; while JB-Weld can perform some tasks that welding can’t, it struggles with simpler welding jobs, such as joining thin metal rods at right angles.

HOW TO USE JB-WELD

General Principles: JB-Weld makes an excellent filler and can even be used to cast small parts, but it doesn’t match the strength of real metal. Use it primarily as an adhesive, applying a thin layer to bond two metal pieces. Reinforce with additional metal wherever possible; for instance, instead of building up a thick flange with JB-Weld, use scrap metal to form the bulk of the flange and secure it with JB-Weld. The larger the contact surface area, the stronger the bond will be.

Surface Preparation: Ensure surfaces are clean and rough. Clean with a solvent (acetone is highly recommended, but rubbing alcohol can work too), roughen the surface, and clean again with the solvent using a clean cloth each time. I often use a small grinding wheel on a Dremel tool for roughening. If your parts have oil, even multiple solvent cleanings may not suffice; consider using a degreaser first. If you lack a commercial degreaser, a paste of laundry detergent and a stiff brush may help. Always ensure there are no traces of oil before proceeding with solvent cleaning.

Joining Broken Parts: For broken parts with irregular matching surfaces, limit roughening to scratching with a wire brush or using acid (ensure to wash off any residue). Apply a thin, uniform layer of JB-Weld and lightly clamp the pieces together to squeeze out excess. A thick rubber band can work well, or you might arrange the pieces so that the weight of the top one holds them until the JB-Weld cures. Avoid removing any clamps or pressure until the JB-Weld has fully set. After an hour or two, you can trim any excess with a knife if necessary, but if it’s not needed, leave it as is. Blue painter’s tape can help hold pieces together while the adhesive sets or provide a temporary stand for proper alignment.

Joining Dissimilar Parts: Minimize gaps by sanding or adjusting the fit. If you’re filling significant gaps, using blue painter’s tape can prevent JB-Weld from flowing away.

Joining Long Thin Parts (rods or sheets): Aim for overlap or reinforce with additional metal glued with JB-Weld. For example, to join two 1/8″ steel rods at a “T” angle, cut two 1″ “L” shapes from a heavy paper clip, embed them with JB-Weld on opposite sides of the joint, and reinforce further with fine steel wire before applying JB-Weld. For small parts, unwaxed dental floss can also serve as a strong reinforcement when embedded in the JB-Weld.

Filling Holes: Always prepare surfaces as mentioned before. Since JB-Weld shrinks minimally during curing, fill the hole completely. If you plan to sand the surface later, overfill slightly. To keep the JB-Weld horizontal, cover irregular surfaces with blue painter’s tape. For large gaps, consider using metal pieces embedded in JB-Weld rather than a solid mass of JB-Weld alone.

Reinforcing a Leaking Pipe: Work JB-Weld into fiberglass cloth, apply it, and add more JB-Weld to reinforce edges. You might need several layers of JB-Weld-saturated fiberglass cloth. Wire cloth can also be effective.

Holes in Car Body Panels: Covering at least one side of the hole with sheet metal secured by JB-Weld is a good strategy; combining pop-rivets with JB-Weld often yields excellent results, even if you sand the rivet heads flush later.

Mixing: Adhere strictly to the instructions. A paper plate serves well as a mixing surface, and popsicle sticks are ideal for stirring. Ensure equal parts of resin and hardener are used, mixing thoroughly; continue mixing for twice the time you believe is sufficient.

Curing: Follow the instructions but allow more time than suggested; the longer you wait, the stronger the bond. A minimum curing time of a day or two at temperatures of 70-80°F is advisable. Remember, epoxy doesn’t “dry” as there are no solvents involved; a chemical reaction hardens the material. Chemical reactions speed up with temperature, so curing at lower temperatures may take significantly longer. While it’s impractical to wait that long in many situations, you might manage with around four hours at 90°F without exceeding that temperature.

WHEN TO USE OTHER EPOXIES

For materials other than metal, especially rigid plastics, other epoxy types may outperform JB-Weld. Some specialized epoxies offer clear or colored options for specific applications.

WHEN TO USE QUICK EPOXIES

Standard epoxies deliver harder finishes than quick-setting alternatives and are generally preferred. Use quick epoxies when rapid hardening is crucial, when the item can’t be supported during the curing process, or when minimizing flow is essential. Super glue can also be a good alternative for these scenarios.

WHEN TO USE OTHER CEMENTS OR GLUES

While epoxies excel in specific situations (mainly for rigid bonds in metal or hard plastic), other adhesives may be more effective for different applications. Epoxies are generally not suitable for flexible surfaces like leather, wood, or flexible plastics and may not bond well to glass. For porous materials (paper, wood, ceramics), other adhesives are often superior.

White Glue: Ideal for light-duty indoor applications that don’t require waterproof properties. Clean up is easy, and repairs can be redone if mistakes occur. However, white glue shrinks significantly as it dries, making it unsuitable for large gaps.

Glue Stick: Think of glue sticks as solid versions of household white glue, primarily effective with paper.

Wood Glue: This type of glue is essentially waterproof white glue that penetrates and strengthens wood better than others. It’s safe, easy to clean, and allows for re-gluing if necessary.

Goop: Extremely versatile, Goop bonds various materials including leather, plastics, glass, and metal. The bond is strong, waterproof, and flexible, making it ideal for numerous repairs.

Silicone Glue: Best for glass, silicone glue offers a flexible bond to absorb vibrations and is a good alternative for general household use on various surfaces.

Fabric Glue: Works exceptionally well on fabrics, creating a strong bond without soaking through. Depending on the application, it may be preferable to sewing.

Super-Glue (Krazy Glue): Known for its strength and quick setting time, super-glue is similar to 2-minute epoxy but requires no mixing. However, it is brittle and not recommended for flexible objects.

Liquid Nails/Construction Adhesive: Ideal for permanently bonding large surfaces of nearly any kind. Slightly flexible, it can even be used on leather for shoe repairs.

Caulking Compound: Useful for filling holes, caulking compound is weaker than other adhesives but can be effective when applied over a large surface.

Hot Glues: A great option for quick-setting glue needs, hot glues come in stick form for use in glue guns and set rapidly, but care should be taken to apply them thinly for maximum strength.

Placeholder –

I purchased this glue to repair my 80lb brass god idol after a few branches were damaged during shipping. I’m pleased to say it exceeded my expectations! Just keep in mind that it requires 24-48 hours to fully cure, so it’s best to secure the pieces together with a zip tie and place them in a low-traffic area during that time. Once it sets, the bond is incredibly strong—like metal—and can support a significant amount of weight as advertised. I highly recommend this product!

Andy G. –

This epoxy repair is unmatched in the market: user-friendly and remarkably durable.

lampstart –

I am very pleased with this product. I used it to rebuild the cylindrical flange on a small vintage internal combustion engine that had a cooling water leak. I allowed the built-up area to cure longer than recommended to ensure it set properly. I needed a clearance of 0.002 inches on a 3-inch diameter, and I achieved that easily on my lathe, resulting in a smooth, hard finish. The engine has been leak-free and has performed well at several shows. Just be sure to clean and degrease the surfaces that need repair thoroughly.

Frank –

Functions effectively. It also requires some time to set, giving you ample opportunity to work with it.

T9zap –

Excellent product! Easy to apply and delivers amazing performance! Used it to repair a carbon piece!

Jack –

As a diesel mechanic with 18 years of experience, I can confidently say that this slow-curing epoxy is highly regarded for its effectiveness in repairs, ultimately saving both time and money. However, for optimal results, it’s crucial to thoroughly clean and degrease the area using something like brake cleaner, ensuring it’s completely dry.

Be sure to follow the curing instructions closely before applying any load or pressure to the repair, as the curing time can vary with temperature—colder conditions will prolong it. While I don’t live in a snowy climate and can’t speak to the exact temperatures that might hinder curing, I do know that allowing more time for curing significantly increases the likelihood of a successful repair.

One particular instance comes to mind: on a large forklift engine, there was a leaking freeze plug located at the rear of the cylinder head. Replacing it wasn’t feasible due to the transmission bell housing covering half of it. Fixing it correctly would have required removing the cylinder head or at least loosening the bell housing. Considering the vehicle needed to be operational to generate revenue for the company, the repair had to be efficient and cost-effective.

I cleaned the area meticulously, degreased it with brake cleaner, and then filled the gap with J-B Weld steel-filled epoxy in stages. I allowed it to cure overnight, and by morning, it was ready to go. Years later, when I changed jobs, that forklift was still in use with no leaks in the repaired area.

Just a word of caution: the success of the repair hinges on how well you prepare the surface. Don’t expect the JB Weld to adhere to greasy or oily surfaces, or areas with loose debris or rust. Proper preparation is key to making it work.

Bill Boedeker –

The epoxy met my expectations and arrived promptly. It performs excellently.